But my first love is pottery

https://tonyhansen.com/pottery

Message me at Digitalfire.com or follow me at

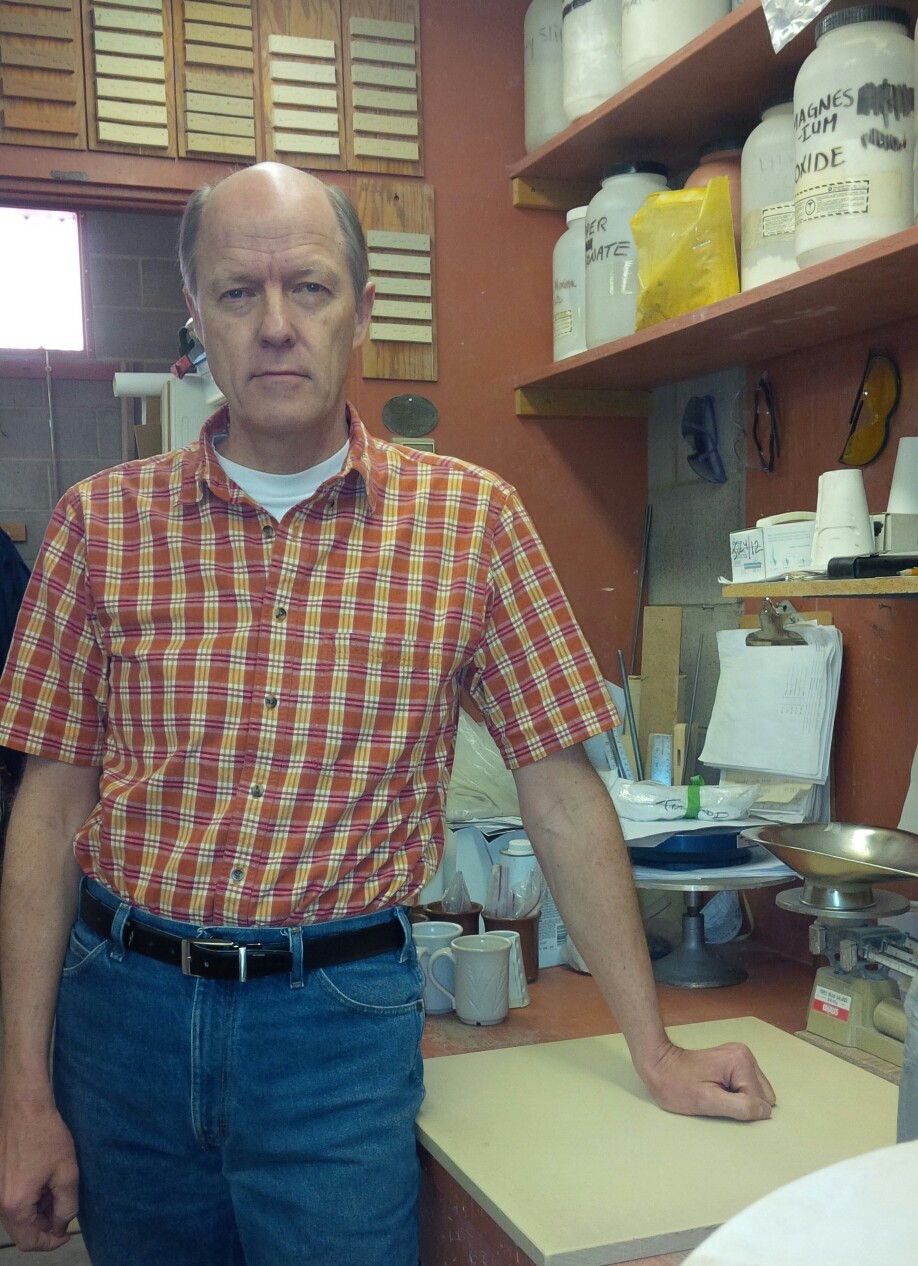

Tony Hansen: Potter

Tony was captivated when he first saw John Porter in action on a potter's wheel (when his father was building the Plainsman Clays plant). He hired on, out of grade 12, and was given unfettered access to the well-equipped plant studio.

-Under the tutelage of John and Luke Lindoe, as both employers and mentors, he developed quickly as a functional potter and lab tech, using all the products and processes that customers did.

-Tony's pottery gallery at https://digitalfire.com/url/3739 shows types of ware made over the years. He describes his pottery, not using craft or art language, but in terms of the way pieces were made.

-The landing page at pottery store https://tonyhansen.com/pottery is an example, each piece has how-to-make-it info.

-Tony is a champion of traditional pottery DIY and understanding the ceramic process. In the early 1970s, starting with techniques learned from John Porter, he began using glaze chemistry to study and adjust glazes. It became a life long fascination that it was possible to predict the fired properties of glazes from their oxide chemistry.

Ceramic Achievements

His Insight software enabled a wider understanding of the relationships between the composite chemistry of a glaze’s raw materials and its fired properties, this armed users with the ability to identify and fix key issues like crazing, crawling, shivering, cutlery marking, and leaching - misunderstood problems that even engineers were not approaching on the chemistry level. To teach, he adopted each new publishing medium as it arrived (diskettes, word processing, desktop publishing, PDFs, CDs, BBSs, the static internet, the data-driven internet, AI). His case studies documented the creation or substitution of important industrial and pottery raw materials (e.g. Gerstley Borate, Barnard Slip, Cornwall Stone, PV clay, Alberta Slip, Ravenscrag Slip). Tony’s LIMS software enabled ceramic labs to store and search large amounts of data to better understand the relationships between the fired physics of bodies and glazes with their recipes. His testing methods documented inexpensive ways to measure degree of vitrification, drying performance and working properties in bodies; melt viscosity and thermal expansion in glazes; body compatibility in engobes. This led to discovering how to make hyperplastic translucent porcelain without the need for bone ash or high temperatures (it became Plainsman Polar Ice). And how to recognize reactive glazes and stabilize and tune their delicate properties. His techniques enabled reworking dozens of long-used glaze recipes and improving crystalline glazes by understanding their technical mechanisms. Tony developed new ways to understand the relationships between viscosity, specific gravity, deflocculation and thixotropy in glaze and clay slurries, important DIY advances for potters. Using his tools, manufacturers learned to better understand and characterize their raw materials. Potters (and their suppliers) learned to be more independent and demanding and recognize quality and safety issues with their own ware and materials they used. Potters (and their suppliers) learned to see and understand industrial frits on the chemistry level and better incorporate them into recipes that had long used unreliable raw materials. He also developed novel ways to use CAD tools and 3D printing to make all manner of molds and tools, making them accessible to anyone.

IT Achievements

By 1980, Tony Hansen had developed early versions of desktop Insight glaze chemistry software. It was quickly adopted by technicians in industry. It was novel enough that he was invited by two Prime Ministers on Team Canada trade missions. It even generated enough funds that Tony was able to personally finance almost all aspects of customer relations, promotion, web development, coding, travel and teaching for Plainsman Clays. During the 1990s, Tony's DOS 4Sight Ceramic Database added record-keeping for physical testing, it became a LIMS system for ceramic labs. Tony's 1995 article in Ceramic Technology International introduced readers to “Database Technology to Empower Ceramic Professionals”. Tony's 1998 presentation at the 101st conference of the American Ceramic Society in Indianapolis introduced attenders to "The Internet". In those years, Tony was well-travelled in the ceramic industry, attending, exhibiting and lecturing at international events.

The record-keeping needs of his job during the day, at Plainsman Clays, provided the direction needed to build his 4Sight LIMS DOS software. The troubleshooting, procedure and information needs of customers gave direction on enhancing it to be an information-gathering system. By the late 1990s, 4Sight could automatically generate a PDF reference textbook called “The Magic of Fire”. In the 2000s, he and his wife lived in Mexico (doing missionary work). This period of reflection and lesser distraction enabled transitioning the PC based system to an online CMS to manage the Digitalfire Reference Library (providing a home to collect and organize the information). As data was collected, it became much bigger than his work at Plainsman Clays (which he realized was one of supporting customers to employ clay products made from inferior materials and teaching them to make their own glazes since the company would not produce them even though competitors were using Tony’s software and published materials to do exactly that). Out of this came the realization that teaching pottery DIY publicly brought satisfaction not found in serving software to manufacturers. His efforts became 100% internet-focused and digitalfire.com became a technical information destination and a way to document all his ceramic achievements.

Tony Hansen at Plainsman Clays - 1973-2025

-Company products are used by many thousands of customers in schools, hobby, pottery and manufacturing. Tony has been at the centre of its operations since the 1970s.

-Luke Lindoe, founder of the company, tutored Tony to mine, develop local clay resources.

-He coded their CRM, CMS, LIMS and tech support systems.

-Personally helped thousands of customers, one-on-one, to solve issues.

-Developed and maintained all product recipes and the testing procedures.

-Coded the MSDS authoring system (by GHS standards).

-Co-directed raw material minings and material characterizations and evaluations.

-Coded the multi-store product database manager and the publish-to-website system.

-Coded the blog and social media posting system and syndication to two dozen platforms/groups.

-Coded the product label management system, templates, linkages to product thedatabase.

-Created the advertising, workshop and trade show materials.

-Created glaze and porcelain recipes and formulation tutorials that came to be used throughout the world.

Programming, IT, Productivity (1978-present)

-Tony has been a programmer since 1978 and web developer since 1995, prioritizing minimalist solutions that run securely and fast. He was among the first in North America to sell online.

-He embraced productivity tools from their 1.0 versions.

-He also embraced the movement away from desktop and spreadsheets towards the databases and the cloud (and their programming languages) during the 1990s.

-Tony developed early skills as a programmer by writing and maintaining multi-user inventory management, purchasing, pick list, warehouse location and costing software.

-Tony was an early adopter of computer graphics and publishing software (bit image and vector), self-publishing PDF manuals and books by the late 1980s.

-Tony coded desktop Insight glaze chemistry software.

-Tony created the technical reference website for traditional ceramics at digitalfire.com.

-Tony created insight-live.com as the first ceramics-targeted LIMS, transitioning his company to a virtual MSP.

-Tony is an API developer and consumer, having a deep understanding of the REST API architecture, JSON data format for inter-server and app-server communication.

-Tony has a thorough understanding of the programmatic generation of labels in HTML, PDF and ZPL formats.

-Tony is a firm believer in "infrastructure as code", task automation and the use of open source software to build and maintain systems.

-Tony is a promoter of CRM tools and has been developing and using them since the 1990s.

-Tony was an early adopter of group collaboration tools.

-Tony's web pages have always placed at the top of Google searches for hundreds of ceramic-related terms.

-Tony is an avid user and developer of social media posting tools and APIs, he publishes thousands of posts on a many platforms, managing synchronization with multiple blogs and reposting when content is updated.

-Tony is an early adopter of AI and machine learning tools, methods and protocols.

-Tony's recent focus is 3D design and 3D printing as they pertain to making molds, cutters, tools, templates, etc for ceramics.

Work Ethic

Tony prioritizes personal relationships, trust, quality-of-work and integrity to principle.

He is a delegator to capable and amiable people, anxious utilize their skills and talents, a mentor sharing his knowledge and experience.

He is a communicator and loves working on a team with clear, sensible and ethical goals.

He is pragmatic, evolving slowly and steadily toward long-term goals.

He excels on the energy of enthusiastic fellow workers who are willing to learn, multi-task, who focus on giving rather than taking.

Companies have trusted him with the privacy and integrity of their cloud and network data for decades (even competitors and suppliers of Plainsman Clays).

For references visit the digitalfire.com home page (under the heading “What people have said”) or feedback on his Ko-Fi.com channel.

Tony is at home at a keyboard, a potter's wheel, a workbench, a podium or using a shovel; he does not use inefficient systems or methods, he steadily improves them.